Vacuum Pumps Australia

Looking for high-quality vacuum pumps? Australia, you’re in luck – Emtivac is on the case! We’re an Aussie-owned and operated engineering company with over 20 years’ of experience in supplying vacuum pumps and associated technology for a wide range of applications including mining, process and manufacturing industries.

We have a highly professional approach to our work – we have highly detailed, inside-out knowledge and expertise in vacuum pumps to ensure that you’re getting nothing but the very best for your project. Not only do we lead the Australian vacuum pump market, but we also have a strong international network – making us the sole agents for multiple vacuum pump manufacturers across the globe.

Keyed into the global market allows us to incorporate the equipment of overseas manufacturers into our vacuum pump systems, allowing us to manufacture comprehensive systems that will be the perfect solution for your needs and requirements.

Our advantage is our experience, proven to provide our clients with practical solutions that boost efficiency and reliability in vacuum pump systems to prevent unexpected breakdowns, which would lead to unplanned production losses. We can assist you with a variety of services – from measuring your vacuum pump’s efficiency, providing energy reports, to reducing your power consumption, often by more than 50 percent, our job is to save you money through reduced maintenance costs.

You can trust that Emtivac is the sure choice for all process industry requirements. Rely on our friendly expert team that will recommend, design, supply and manufacture cost-effective solutions for your business. Whether you’re looking for an on-site equipment appraisal or an efficiency audit, send us an online enquiry or give us a ring on (03) 9768 3240 today!

Claw vacuum pumps use a claw-shaped rotor to trap and compress gas. They are known for their high efficiency and ability to handle harsh environments.

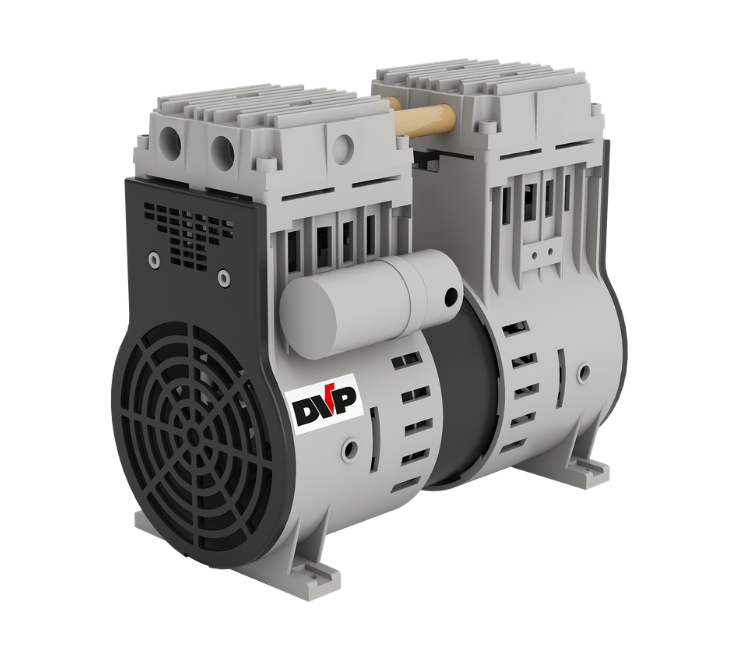

Diaphragm pumps use a flexible diaphragm to move gas. They are oil-free and can handle corrosive or contaminated gases.

Dry screw pumps use two intermeshing screws to compress gas without using any lubricating oil in the compression chamber. They are known for their clean vacuum and ability to handle high humidity environments.

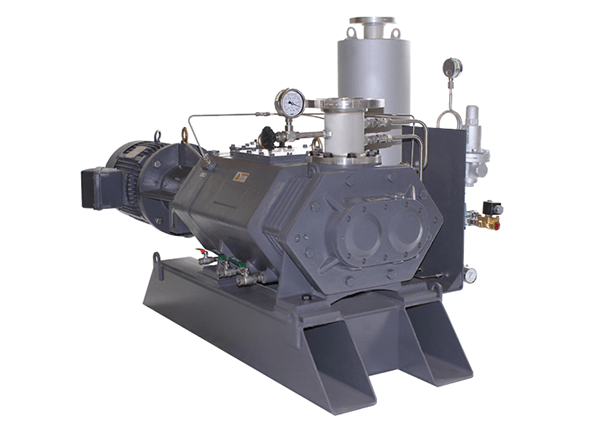

DVP Booster pumps are used to increase the pressure of an existing vacuum. They are often used in combination with other vacuum pumps to achieve very high vacuum levels.

High vacuum pumps are used to create very low pressures. They are often used in research and development applications.

Liquid ring vacuum pumps use a liquid ring to compress gas. They are known for their simple design and ability to handle large volumes of gas.

Piston pumps use a piston to trap and compress gas. They are positive displacement pumps, meaning that they can move a fixed volume of gas per cycle.

Rotary vane pumps use a rotating vane to trap and compress gas. They are known for their simple design and low cost.

Steam ejectors use steam to create a vacuum. They are often used in industrial applications where large volumes of gas need to be evacuated.