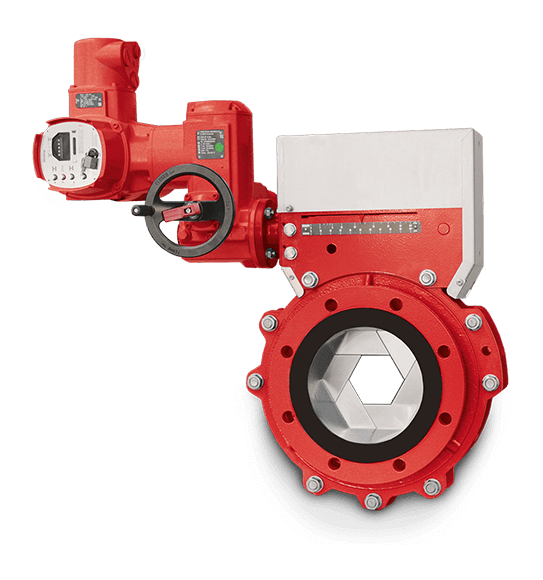

Iris Diaphragm Control Valve

Energy saving valve for the precise and economical control at low loss of pressure of liquids and gases that can be either clean or contain particles.

- Highly precise control of the flow rate through concentric Iris® diaphragms (similar to a camera diaphragm)

- Energy-saving control valve due to its free centric passage

- Maintenance free

Nominal dimensions: DN 25 – 400 mm

1 – 16″

Pressure: up to 10 bar

150 psi

Temperature: up to 220°C

428°F

Materials:

- Casing: GG, 1.4409, 1.4588

- Segments: Bz hard chromeplated, 1.4404, 1.4529

- Special materials on request

Air for aeration in wastewater treatment plant : Used to regulate the aeration, this valve has been proven thousands of times at wastewater treatment plants. Due to the enormous energy saving, Iris® diaphragm control valves recover cost rapidly in wastewater treatment plants. In combination with an ABB Sensyflow® mass flow meter, cascade regulation with slave loop according to ATW can be assured.

Liquids and gases in chemistry and industry: In chemistry and industry, the BSH design is used for higher system and differential pressures. It is prepared for various monitoring systems and exists as all Iris® diaphragm control valves also in Atex design. The industrial design BSH fulfills the requirements of the Technical Guidelines on Air Quality Control (TA-Luft).

Municipal and industrial wastewater: Centrifuges such as in the sugar industry or wastewater technology, can be fed accurately by Iris® diaphragm control valves.

Slurries and viscous materials: Even slurries, solid containing liquids and fibrous products can be regulated precisely. The Iris® diaphragm control valves avoids clogging due to its completely open circularshaped passage.

- Paper pulp and fibrous suspensions

- Pellets with a particle size over 0,5 mm

- Drinking water