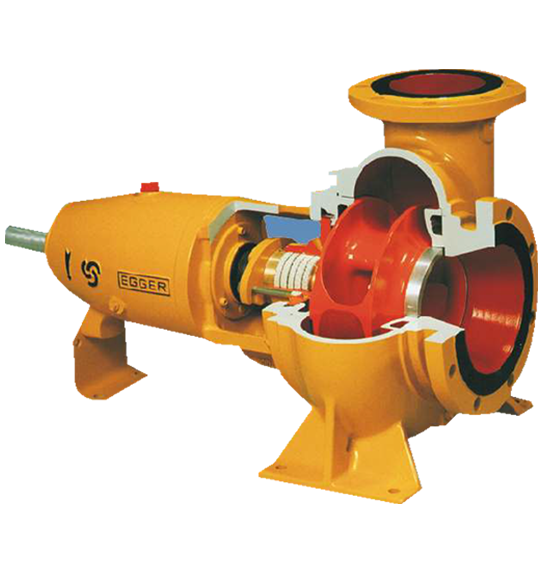

Single Stage

FM/FMV-axially Split Centrifugal Pumps

Double Suction

Horizontal & Vertical Execution

Single & Two Stage

Max Capacity 833 l/sec (3,000m3/hr) at 200m up to 2900 rpm

General Industry and process, Building services and HVAC, Fire protection, Irrigation – Water supply and Booster pumps, Marine applications.

- FM/FMV are of an advanced hydraulic design, with precision construction in materials to suit most applications.

- FM/FMV will give trouble free efficient operation with the minimum of maintenance over many years. This is due to good efficiency zones which produce low noise and vibration characteristics, plus they are energy efficient.

- Range: A comprehensive range spanning over 50 models, designed around seven shaft groups. Nominal impeller diameters range from 300mm to 660mm. Duties can reach to 800l/sec with heads up to 230m.

Similar Products