TMHP

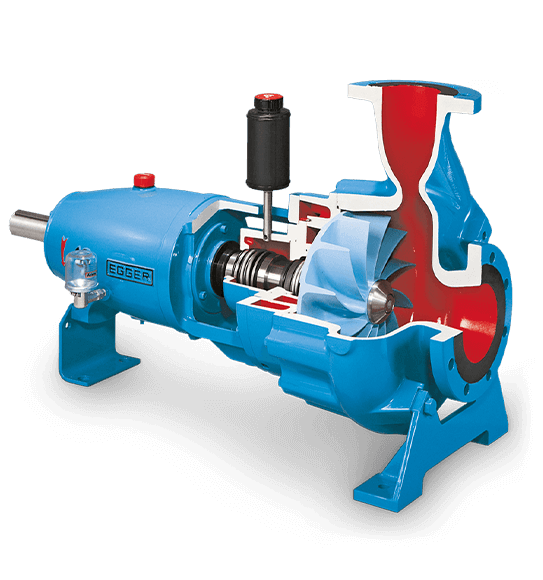

Horizontal multistage centrifugal pumps in ring-section design

Multistage centrifugal pumps in ring-section design, radially split, with closed radial impellers and suction impeller at 1st stage for lower NPSH values. Casing parts sealed by O-rings and assembled by robust tie bolts positioned externally at suction branch. Radial suctionand flow inlet which can be rotated every 90°. Flanges according to DIN and ANSI (drilling, sealing step and flange thickness)

DN suct./disch. 32/150 and 50/250

Q up to 800 m3/h (220 l/s)

H up to 650 m

max P up to 64 bar

max T from -20°C to +180°C

Speed up to 3600 rpm

Standard flanges DIN

Suction inlet PN 16

Flow inlet PN 64

BEARING

Flanged greace or oil-lubricated bearings on both pump sides. Axial balance on the open side by special bearing well suitable against axial thrust. Radial balance on operating side by roller bearing. Heavy antifriction bearing available for high pressure conditions.

AXIAL THRUST

Pumps equipped with balance drum for the hydraulic balancing of the impeller axial thrust. Residual thrust absorbed by axial bearing.

SHAFT SEALS

Cooled or uncooled packing stuffing box, with or without barrage fluid injection. Single or double mechanical seal in accordance with DIN 24960, cooled or uncooled.

COUPLING

Base with either direct coupling pump/electric motor, with elastic coupling on suction side; or steam turbine; or indirect coupling by speed reducer. Clockwise direction of rotation from operating side. Robust anti-twist base in U structural steel; whole unit polished (pump + motor).

- Washing plants

- Artificial snowing plants

- Irrigation plants

- Heating plants

- Cooling plants

- Reverse osmosis plants

- Superheated water plants

- Boiler feed plants

- Condensate lift plants

- High pressure lift plants

- Water feed and anti-fire plants