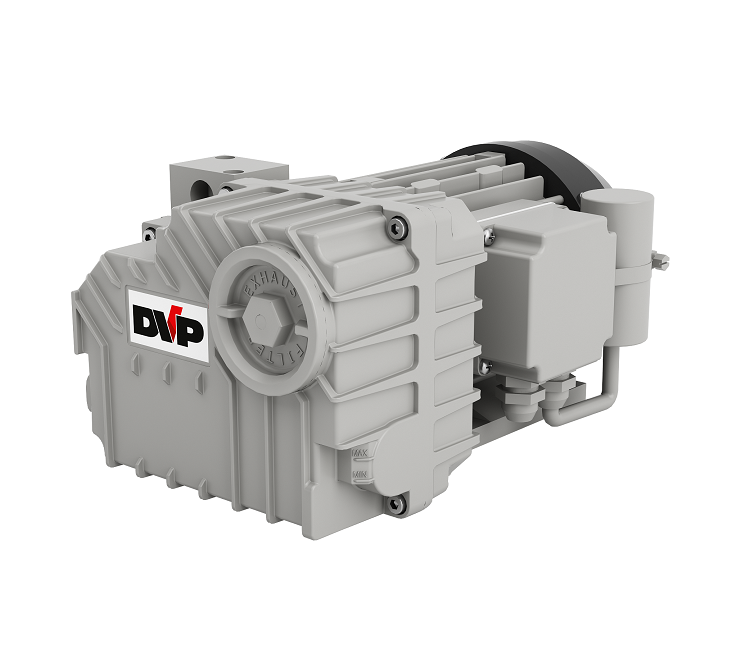

XC 405 / XC 605 / XC 905

XC systems, with two or three lubricated rotary vane vacuum pumps, can replace high flow rate single-pump units. So therefore XC systems offer many advantages: small dimensions, modular operation (i.e. if 100% of flow rate is not needed, it is possible to optimize the usage thus reducing the energy consumption significantly), reduced maintenance costs, reduced power required, absence of start-up surges; furthermore it is possible to carry out maintenance of the XC system without interrupting work.

PLC is fitted with a thermal protector, a general off switch, and on switches for each pump and hour counter. XC systems are suitable to suck continuously between a pressure range of 400 and 0,5 mbar (Abs.).

The XC systems are equipped with:

- Exhaust mist eliminator

- Inlet filters

- Clogged filter gauge

- Gas ballast

- Oil check valve

- Pack of BV100 oil

Main application fields: food packing and food processing.

| Nominal capacity | Maximum water vapour pumping rate | Total final pressure | Motor power | |

| m³/h 50 Hz / 60 Hz | kg/h | mbar (Ass.) | kW 50 Hz / 60 Hz | |

| XC 405 (1) | 410 / 410 | 7 |

0,5

|

2x 5,5 / 2x 5,5 |

| XC 605 (2) | 610 / 610 | 10 |

0,5

|

2x 7,5 / 2x 7,5 |

| XC 905 (3) | 915 / 915 | 15 |

0,5

|

3x 7,5 / 3x 7,5 |

| Notes | (1)2xLC 205 | (2)2xLC 305 IE3 | (3)3xLC 305 IE3 |